A dramatic encounter between a ute and a large crocodile at one of Australia’s busiest croc crossings has grabbed the attention of nearly four million viewers online.

The video, shot at Cahills Crossing in Kakadu National Park, shows the crocodile getting stuck under the vehicle as it crosses the shallow East Alligator River. It was posted on TikTok and Facebook by Matteo Mastratisi and quickly went viral.

Cahills Crossing is notorious for its dense crocodile population and unpredictable, fast-changing conditions. The narrow, submerged causeway cuts through the East Alligator River, which is home to some of the highest concentrations of saltwater crocodiles in the country.

Despite repeated warnings and visible signage, both locals and tourists are often drawn to the crossing – whether out of necessity or curiosity – and many underestimate just how quickly things can go wrong. Incidents like this serve as a clear reminder of the serious risks posed to both drivers and wildlife in remote parts of the Top End.

The driver was reportedly unaware the crocodile was beneath the vehicle, and experts told the ABC they would be surprised if the animal sustained any lasting injuries.

Authorities keep stressing caution around the crossing, where encounters between vehicles and saltwater crocodiles happen regularly – especially in the dry season when water levels drop and visibility is poor.

Last year, a family caused outrage when they were filmed fishing and letting a small child play just metres from the water’s edge – despite plenty of warning signs and large crocs nearby. The footage, captured by a local tour operator, underlined just how dangerous complacency at Cahills Crossing can be.

Crocodile safety in northern Australia means always assuming crocs are near any water source, camping at least 50 metres from the water’s edge, avoiding walking close to the water at night, and planning river crossings and campsites carefully to avoid close encounters.

The Ranger really needs no introduction.

It’s the top-selling ute in this country for a host of good reasons – not least the fact that, unlike almost all of the others, it’s got a powerful 600Nm V6 engine (why manufacturers think 450Nm of peak torque is acceptable in this day and age I’ll never understand). The Ford also just looks hot when lifted on some larger rubber – and sex appeal sells.

They’re a well-proven thing these days, and there aren’t too many applications where the Ranger can’t be made to shine (maybe heavy towing, but no mid-size is amazing in that regard, so we won’t count that as a negative).

The four-banger twin-turbo is nothing to sneeze at, but while turbocharging has challenged the “there’s no replacement for displacement” crowd for a long time now, having more displacement, two extra cylinders and forced induction makes the V6 the better buy for my needs.

Unfortunately, the V6 is only available in three models: the Raptor (up over $90K), the Platinum (north of $80K) and the XLT (which still hurts, but much less, at $68,840). This raises the question: can you build a better Raptor for the same price if you start with an XLT? Yes. Yes, you can. Right this way, sir/madam.

As with the V6 Everest, the Ranger’s ECU features rolling code that effectively prevents any new code being added – which is essentially what a tune does – so I’d go with a Steinbauer module for $2750 and grab 295hp and over 700 reliable Newtons for my trouble. I reckon that has to be one of the best bang-for-buck upgrades on any 4×4 this side of bolting a junkyard turbo onto a TD42 and winding the fuel up. An exhaust isn’t really necessary – the stock pipes are already 2.75-inch – so an upgrade is only required if chasing bonkers power, which I’m not.

From there, it’s a front Rival bar and a good set of driving lights, as I’m regularly leaving for trips late Friday night and getting to camp in the wee hours. The Rival is roughly $3000, and I’d be keen to run the Big Red LEDs, which are super affordable at under $400 with a harness and reportedly offer better-than-decent performance too.

For a winch – important, as I do a lot of solo trips – I’ve found over the years that most of the ones at or under the $500 mark have hit-and-miss build quality and reliability, whereas spending $1000 or so gets you something good. I’d hit up Superior Engineering and grab a Runva 11XP and call it done.

The Ranger also has a hefty 146-inch wheelbase, so a set of $1500 sliders from Offroad Animal is a wise investment. This gives us a rig that’s barred up, has self-recovery covered, and is significantly faster than stock – but we’re competing with a Raptor here, and one thing the Raptor has that we don’t have is suspension. We should probably change that.

Fox Shocks (standard on the Raptor) are hard to beat, but they’re not perfect. After dropping around $9500 at Solve Offroad, we’d have the same shocks as a Raptor – but better. Things like mounting, spring lengths, shock travel and internal valving are tailored to my Ranger specifically, and the upper control arms up front are swapped out to maintain the appropriate suspension geometry. After that, a fresh set of 286/75R17 Falken Wildpeaks will take up the last $2000 of my budget.

How’d we do? We have a Ranger that’s more protected than a Raptor, way more powerful than a Raptor, has better suspension than a Raptor – and cost us slightly less than a Raptor. I’d say that’s money well spent.

Down the track, when my money tree recovers from the severe pruning I just gave it by buying this thing, I’ll be looking at an extra $5K or so on a front locker (twin-locked is still better than any traction control… just) and a lithium set-up for extended stays at camp. But that’s me.

With the canopy being loaded with electrical appliances that need a power source, we went searching for a reliable lithium battery solution that would fuel our requirements. Finding the right battery that is also Australian made was a bonus.

Custom Lithium is a Queensland-based company that makes all of its batteries at its Brisbane facility, allowing it to tailor its products to suit the needs of Aussie users, and to provide reliable, local aftersales support.

When we headed out to Custom Lithium to talk about our requirements for the VDJ79, they immediately suggested their slimline battery. Although this battery is primarily designed to fit in behind the back seat in the double-cab Cruiser, we were assured that it would also work well in our preferred position in the canopy, where it would be accompanied by all the ancillary electricals we had fitted… with the bonus that it would take up less space than most similar capacity batteries.

The next-gen Ultra Slim 200Ah battery measures 610mm (L) x 405mm (H) x 71mm (W) and weighs 22kg, and it’s that thin that it allows us to tuck it up against the headboard of the canopy where it takes up very little space. We needed to mount it upside down to have the terminals on the near-side of the vehicle but being a lithium battery it can be mounted in any position except with the terminals at the bottom.

The battery comes with sturdy mounting brackets and all the hardware needed to fit in with the system. It has an inbuilt BMS with protection against overcharging and overheating.

With plenty of lithium products coming into Australia with unknown origins, it’s reassuring to know that the Custom Lithium battery is made locally and you have the support of a local company. In fact, Custom Lithium offers lifetime customer support on its batteries which themselves are covered by a seven-year warranty.

Custom Lithium can also supply all the hardware extras to get your battery hooked up and running, but ours is wired in via a Redarc Alpha50 BCDC 50A charger and ancillaries – more great Australian-made products!

Once all the hardware was fitted and wired up, it fired into life straight away for the Redarc system to go through its setup procedure. The battery had been sitting in the shed for a few months and was down to around 30 per cent charge but it only took a few hours on the charger to bring it up to full capacity, and that’s been maintained on the road since then.

With the 2000W inverter, a pair of fridges and an induction cooktop to power, there’s plenty of work for the battery to do, but this Custom Lithium Ultra Slim has so far proved itself to be up to the task.

Custom Lithium has a wide range of batteries to suit many different applications and loads so the company is bound to have a great Australian-made battery for your 4×4.

RRP: $2180 (including shipping)

From Cape York to the garage: ARB’s origin story

ARB was founded in 1975 after Anthony Ronald Brown (Tony) returned from a trip to Cape York in his Land Rover Series I.

Witnessing the punishment dished out by the rough roads and tracks of the time, he saw a clear need for stronger, more reliable accessories for 4×4 vehicles. Back home, he got to work in his garage, using a homemade pipe bender and a 130A stick welder to build roof racks and bullbars.

Within a year, Tony had moved into a small factory in Ringwood, Victoria, and hired his first employee, John van den Eynden. John would remain with the company until the 2020s, eventually managing ARB’s Thailand operation from its inception in 2006 until his retirement.

Around that time, Tony’s brother Roger joined the business, followed a few months later by their other brother, Andy. All three were hands-on and mechanically minded. As Andy recalled with a laugh, “I had a small workshop back then and we used to buy secondhand VW Beetles out of the Melbourne Trading Post on Thursday mornings, fix them up, give them a coat of paint and sell them on the weekend through The Age classifieds.”

Expansion, family ties and early milestones

By the time Andy joined his brothers in 1977, they had established their second dedicated factory in Ringwood.

Their first multi-unit order soon followed – 10 front bars with wheel carriers to suit VW Kombis, commissioned by Sunshine Campervans. In July that year, ARB Engineering was officially formed.

The 4×4 industry was still in its infancy back then, with Andy recalling, “You know, in the ’70s, one vehicle in 25 was a four-wheel drive. Now, nearly one in two vehicles on the road is a four-wheel drive!” As the market share of 4x4s has grown, so too has the industry – with ARB leading the charge, not just in Australia but around the world.

By 1978, with vehicles like the LandCruiser BJ40 and Nissan G60 gaining popularity among recreational four-wheel drivers, ARB had taken on the role of distributor for Old Man vanEmu (OME) shock absorbers (founded by John Chapman in 1976), along with Gabriel shocks, Lovell Springs and Cibie driving lights. These were soon joined by AVM free-wheeling hubs, Warn winches, Topkat canopies and later, Brahma canopies – all while ARB continued building an expanding range of roof racks, bullbars and ladders.

I was one of those aspiring recreational four-wheel drivers back then, and with a 47 Series LandCruiser to my name, I visited the ARB factory in search of a bullbar and roof rack – the beginning of a long association.

Engineering innovation and ASX listing

In 1981, with more than 20 staff on the books, Tony developed the upswept wing design for ARB bullbars – a feature that improved approach angles while preserving the renowned animal-strike protection. Today, that upswept profile is a hallmark of nearly every bullbar design around the world.

In 1986, after two more moves to larger premises and a distribution network that covered the country, ARB moved to its new, much improved headquarters at Croydon, Victoria and with more than 5000m² of work space they again increased production of their barwork. Around this time Tony stepped away from ARB, buying a cattle property in the Victorian High Country and leaving the day-to-day running of the burgeoning empire to Roger and Andy.

The following year was a big one with ARB buying the Roberts Diff Lock, remodelling and improving it, and launching it as the ARB Air Locker on both the Australian and the American markets where it became an immediate success. As well, the company designed and manufactured its own 12V air compressor to be used as a stand-alone compressor or in conjunction with its Air Locker.

That year culminated in ARB being listed on the Australian Securities Exchange (ASX) where it is still a major player. The following year I took over as Editor of 4X4 Australia and I was advised to buy some ARB shares. I wish I had!

In 1988 ARB took over OME after a bidding battle with its then nearest competitor, TJM. With that purchase ARB could boast a full suspension range of springs and shocks and associated hardware.

For many years OME shocks came out of the Monroe factory in South Australia, built more and more to ARB’s increasingly strict standards and the requirements of coil spring vehicles, which were led here in Australia by the Nissan GQ Patrol and quickly followed by the Toyota 80 Series LandCruiser. Yeah, we know the Range Rover had coil suspension first, but you could never say it was very popular or took the Australian 4×4 world by storm… as good as it was.

The Nitrocharger twin-tube shock has long been the mainstay of the OME range and with continual improvement to construction, shaft size, multi-disc compression valving, oils and nitrogen gas, it is still relevant today, offering great value-for-money and unequalled performance in its price range.

R&D, global growth and the Bilstein partnership

In 2015, Old Man Emu expanded its line-up with the introduction of the BP-51 range – high-performance, remote-canister, internal bypass shock absorbers that are user-adjustable and designed to deliver improved comfort and control on- and off-road.

Having just returned from a long outback run that included the Gunbarrel and Gary Highways, along with plenty of punishing tracks, in a BP-51-equipped 200 Series Cruiser, I can personally vouch for the quality of the ride – it stays composed and controlled even after hours of corrugations and through savage whoopty-doos.

Never one to stand still in the suspension game, ARB teamed up with globally respected shock absorber manufacturer Bilstein in 2022. Bilstein now manufactures the Nitrocharger Plus range, and ARB manufactures the MT64 and BP-51 in its Thailand factories. When news of the partnership first broke, it struck me as a perfect union of engineering expertise – a blend of technology and experience that few other shock or 4×4 accessory brands could hope to match. Strangely, ARB hasn’t made a bigger deal about it.

In a major step forward for its expanding camping gear range – which already includes roof-top tents and fridge/freezers – ARB launched the Earth Camper in Australia in 2023. Backed by over five years of design and development, the camper is built at ARB’s manufacturing facility in Thailand. While it hasn’t quite achieved the level of success or market penetration originally expected – Australia’s camper trailer market is fiercely competitive – the Earth Camper has now been launched in the USA, where it’s gaining momentum. With ARB’s ongoing focus on refinement and quality, both production and sales have ramped up.

Then there’s ARB’s OEM involvement, supplying 4×4 accessories to major vehicle manufacturers – most recently seen in the Ford Ranger line-up. When I asked Andy about the upcoming Ford Ranger Super Duty, due to arrive in Australia early next year, and whether ARB had any input, he was understandably tight-lipped. “I’m not sure what I can tell you here,” he said, “but I can say we have nothing to do with the suspension.”

While all this technical development was underway, ARB was also making significant moves on the manufacturing and distribution front.

A 50-year legacy – and what’s next for ARB

No manufacturing business thrives without a strong retail network, and in ARB’s early days, stores like Traction 4 in Sydney (owned by Norm Needham) and Northern 4WD in Melbourne (run by Rob Kay) set the benchmark others aimed for.

Fast forward to today and ARB boasts more than 70 retail outlets across Australia, supported by around 150 stockists and independent dealers nationwide – meaning you’re never too far from an ARB supplier, no matter where your travels take you.

With global demand on the rise, ARB established a manufacturing facility in Thailand in 2006 – a logical move given the presence of major Japanese ute and pickup factories in the region. What began as a 16,000m² operation has since expanded to a massive 96,000m², making it ARB’s largest production site worldwide. Today, the facility employs over 700 staff and houses more than 120 CNC machines cutting, bending and shaping components at scale.

That’s not to say ARB has turned its back on Australian manufacturing – far from it. Despite increasing challenges from government policy that often runs counter to public statements, ARB continues to produce a significant portion of its gear right here. From its Kilsyth facility in Melbourne, nearly all barwork for the Australian market is manufactured, along with every Air Locker differential and ARB air compressor sold globally. Over in Dandenong, a world-class distribution centre keeps products flowing to markets across the planet.

ARB’s canopies are built at its dedicated facility in New Zealand, while its rotomoulded products – including bullbars and fuel tanks – are manufactured at its factory in South Australia.

With the North American market booming, ARB now operates three major distribution centres in the USA – one on the west coast in Seattle, another on the east coast in Jacksonville, Florida, and a third in Texas, which also services South America. In 2023, ARB acquired a 49% stake in US-based Nacho Lights, followed in 2024 by strategic partnerships with 4WP (4 Wheel Parts) and Offroad Warehouse, giving ARB direct access to more than 70 4WD retail outlets across North America.

ARB’s European distribution hub is based in Prague, Czech Republic, supported by additional centres in the UK. In the Middle East, distribution is handled from the UAE.

All up, ARB distributes its products to more than 140 countries and directly employs over 2500 staff, with a further 700 working across its various partner companies. As the company marks its 50th anniversary this month, it’s also celebrating a strong presence on the ASX, with a current share price hovering around $30 and a market capitalisation of approximately $2.5 billion.

After a three-hour wander through ARB’s Kilsyth factory and new office complex, I asked Andy what the future holds following such a stellar 50-year run. His response was typically measured: “Well, I think we’ll be doing a bit of consolidation and working on making the things we do better, even more reliable – and keeping our costs down so our products offer even better value to our customers than they do now.”

That’s good news – but I couldn’t help feeling there was more going on behind the closed doors of the engineering department than Andy was letting on. Either way, the future looks bright for this proudly Aussie company. Like many others, I’m keen to see what ARB pulls out of the hat next as it continues to expand its global footprint in the 4×4 accessory game.

In the meantime, we should all be proud of ARB and the ground-breaking role it has played in not only rising to the top of the global four-wheel drive accessory market, but also paving the way for many other Australian 4×4 equipment manufacturers to follow.

It’s a remarkable legacy for a company that began in a backyard garage, sparked by the ideas and determination of one man, Tony Brown, and carried forward by the vision and commitment of his brothers, Roger and Andy Brown.

ARB timeline

| Year | Milestone |

|---|---|

| 1975 | Tony Brown starts building roof racks and bullbars in the family garage. |

| 1976 | First ARB factory (93m2) opens in Ringwood, Victoria. |

| 1986 | ARB moves into a new 5000m2 headquarters in Croydon. |

| 1987 | Acquires Roberts Diff Lock (Air Locker), develops 12V compressor, and lists on ASX. |

| 1988 | Acquires Old Man Emu (OME), expanding suspension range. |

| 1997 | Launches first airbag-compatible bullbar, crash-tested with Monash University. |

| 1998 | Begins designing and manufacturing canopies. |

| 1999 | Relocates to current Kilsyth HQ and factory. |

| 2003 | Acquires Kingsley Enterprises and Bushranger 4×4 Gear. |

| 2005 | Launches own line of 4×4 recovery gear. |

| 2006 | Opens 16,000m2 manufacturing facility in Thailand (now 96,000m2). |

| 2008 | Launches ARB fridge/freezer – future best-seller. |

| 2012 | Introduces Intensity LED driving lights. |

| 2014 | Establishes ARB Europe, acquires SmartBar, launches Ascent canopy. |

| 2015 | OME releases BP-51 bypass shock absorbers. |

| 2016 | ARB Middle East opens; Frontier polymer fuel tank launched. |

| 2017 | Opens global distribution centre in Dandenong. |

| 2019 | Establishes ARB New Zealand. |

| 2020 | Acquires UK-based Truckman 4×4 Accessories. |

| 2021 | Begins $30M redevelopment of Kilsyth HQ and factory. |

| 2022 | OME partners with Bilstein. |

| 2023 | Launches Earth Camper; takes 49% stake in Nacho Lights USA. |

| 2024 | Partners with 4WP and Offroad Warehouse; gains access to 70 US retail outlets. |

| 2025 | Celebrates 50 years; ASX-listed with ~$30 share price and ~$2.5B market cap. |

There’s been a growing push from some coastal councils to restrict the use of 4×4 vehicles on popular beaches … and I can’t blame them, either.

While some beaches have had their problems with 4×4 drivers not doing the right thing – driving on vegetated dunes and showing little consideration for wildlife such as nesting seabirds – this hasn’t been the main reason behind the restrictions or talk of outright bans.

The real issue comes down to numbers: the sheer volume of vehicles using the beaches has become a risk to both wildlife and other beachgoers. With so many vehicles running up and down the sand – and not all of them being driven responsibly – it’s become too much to manage.

We’ve become a victim of our own popularity. With the take-up of new 4x4s – including the Ranger and HiLux now being the top-selling vehicles in the country – plus a new wave of enthusiasts discovering the joys of getting off the beaten track, there are simply too many vehicles on beaches where families are trying to relax and swim.

Not only are there more 4x4s on the tracks than ever, but there are more people on the beaches too. The general migration away from capital cities has seen plenty of people move to the coast – and come holiday season, the crowds arrive in force. Having all these people on the beach alongside moving vehicles is a recipe for disaster.

In many coastal communities, where fishing is part of the lifestyle, four-wheel driving has long been accepted. Locals have been throwing the rods into the back of the fourby to hit their favourite fishing spots for decades – and by and large, they’ve done the right thing. Understandably, these same locals have been among the loudest voices against any talk of regulating or banning beach access for 4WDs. Some of them are older, and walking down the beach carrying all their fishing gear just isn’t a realistic option.

Some councils have recognised this, and one option that’s been considered is removing one- and three-day beach driving permits altogether – instead offering only six- and 12-month permits. The more expensive, longer-duration permits should be enough to put off the weekend warriors and blow-ins that come to town, while the locals could still buy their annual passes for regular access.

Regulation or banning? I know which one I’d prefer – and it’s good to see some sensible compromises being made to keep beach access open for those who actually use it properly.

The real test will be enforcement. Whether these permit systems can be policed properly remains to be seen.

We put the BLUETTI MultiCooler B70 portable fridge and battery pack to test on the sands of Fraser Island, in the weeks following the arrival of Tropical Cyclone Alfred.

Despite heavy rain, salt spray and no external power for over three days, it kept all our food and drinks ice-cold without a hitch. Secured only with ratchet straps on the tray of our LandCruiser 79 Series – on a lightweight plastic shell and with no canopy – the battery still lasted the full three days as promised.

Durable, lightweight build and portable design for off-road use

The cooler weighs 24kg and is built from moulded ABS plastic, which keeps the weight down while offering solid resistance to the elements. Its compact dimensions (710 x 420 x 475mm excluding wheels and draw bar) make it easy to fit on a tray or rooftop rack.

The extendable handle and wheels make moving it around camp straightforward, though the grab handle is a bit short and tends to bang into your legs if you’re not paying attention. It’s designed with weekend warriors in mind, rather than permanent installation as a drawer fridge or bull-bar mount. The unit comes with a two-year warranty.

Fast, efficient cooling and ample storage capacity

With a total capacity between 40 and 55 litres (42L fridge, 9.5L freezer, and 6.3L battery compartment), the MultiCooler easily handles a weekend’s worth of food and drinks with room to spare. Its Huayi compressor and efficient cooling technology can drop the internal temperature from 30°C down to 0°C in just 15 minutes. It runs whisper-quiet at around 30dB when in fridge mode and under 45dB when making ice. The built-in ice maker produces clear, crystal-cube ice – a handy feature for those warm Aussie days.

Long-lasting LiFePO₄ battery and multiple charging options

The removable 716.8Wh LiFePO₄ battery connects in seconds and powers the fridge for up to three days without external input. Rated for over 3000 life cycles, it should handle many trips before showing wear. You can recharge the battery four ways: via AC power (up to 200W with adapter), solar panels (up to 200W), or other compatible power sources. The MultiCooler also has a 100W USB-C port and a 15W DC outlet to charge phones, lights or other small devices while you’re on the move. On Fraser Island, it ran nonstop for three days on battery alone, exactly matching the manufacturer’s claim.

User-friendly controls and handy remote app functionality

The control panel features a clear LCD display and simple up/down toggles that work well even with muddy gloves, though wet fingers can make it a bit fiddly to use. For extra convenience, the MultiCooler can be controlled remotely via the BLUETTI app, letting you adjust settings from around camp. The ice maker requires you to add your own water and pull the lid firmly to eject ice cubes, but it’s a useful addition for long days in the sun.

Verdict: Reliable portable fridge and freezer for off-grid adventures

At just under $2000 for the fridge and battery pack, the BLUETTI MultiCooler B70 offers a genuinely portable and tough cooler/freezer/ice-maker combo. It’s not a luxury drawer fridge, and the plastic housing means it’s best suited to occasional campers and weekend warriors rather than permanent installs.

Still, for surf trips, beach days and post-cyclone adventures, it delivers reliable cold storage that stands up to harsh Aussie conditions.

Building a tourer today usually takes a well trodden path, ultimately ending with an absolute rig holding everything you’d ever want while you’re away from the place you actually have everything you’d ever need.

Before the 4×4 industry’s big bang that exploded thousands of products onto the market to satisfy the consumer-tourer, 4×4 owners did things much simpler, and for good reason. Weight. In simple terms, more of it meant it was harder on the rig, and took much more fuel to move it all, limiting range. Engines were upgraded with more power, with chassis becoming heavier still for higher GVMs, and the gear list longer still. And the cycle continues.

While it seems the favoured choice is to go heavy and hedonistic, there’s still those who pack light and limited, but Mandurah local Bo Clayton entered the chat with a third alternative: a super tourer that packs the most power in his chosen model range, along with the race-inspired Fox suspension, but with a fully spec’d lightweight canopy ready to lap the map. While this seems like mixing oil and water, Bo had a plan to pull it off.

“I wanted a comfortable vehicle to travel Australia in and what I got for the price I thought was value for money,” Bo explains. “If you look at all the extras the Raptor has over the lower-spec vehicles, I believe it was a cost effective price.”

Experienced 4×4 builder

Coming from a decent list of past 4x4s which included the previous 2022 Raptor, a 1982 Bronco, a 2004 Hummer H2, two Hiluxs, a Surf and a 2020 LC200 VX, Bo had a good idea what sort of a challenge he was in for. “The 200 Series turned out really well but she ended up being four tonnes, and I did not enjoy driving it that much,” he admits.

Taking on the range-topping 2024 Ranger Raptor to build a tourer from was still a bold choice, bearing in mind it came with a reduced payload just above 700kg straight out of the factory. This represented a restriction of 200kg less than the marque’s leaf-sprung alternatives, mainly due to its race inspired all coil suspension. The Raptor is also the heaviest in the Ranger range, albeit with the most power, but with no adjustment from Ford to the final GVM allowance.

“The biggest challenge was to keep the Raptor under the 750kg payload with the super lightweight canopy, but I managed to accomplish that task,” Bo says. “I have all the weighbridge receipts, so I know it’s correct.”

Lightweight canopy

To give his Raptor a decent chance to stay within its GVM, Bo decided on the Mode 4×4 canopy, which is a subdivision of parent company Zone RV caravans.

According to Mode 4×4’s website, these composite canopies come in at a svelte 220kg, and are a bolt-on service-body style, so there’s no additional weight from a tray or headboard, with the wheel arches and toolboxes bolting straight to the underside of the canopy.

Installing the canopy was taken care of by David and Jayden at Mac 4X4 in Cockburn, south of Perth. While they were at it the crew also installed an Offroad Animal bull bar, plus a complement of 13 Stedi spot, bar and work lights. The job of colour coding to the Raptor’s Code Red hue was handed to Nathan, Vaughan and team at Calmack Panel & Paint in Greenfields, who also turned their attention to detailing the bull bar and bash plates, and modifying the front mudflaps.

While all this sounds like it was trucking along seamlessly, there were the usual supply delays and workshop availability issues. When asked what he’d do differently Bo said, “I’d compile most of the components and store them for about five months until I had enough to start and finish the build in a better time frame. This would save a bunch of money for a start, so you can imagine just how hard it is to complete a build when you have assorted components coming from all over Australia and overseas, all arriving at different times.”

Once the canopy was painted Bo engaged 4Signs in Mandurah to draw up his own design of custom graphics with inlaid skull detailing, plus a PPF wrap. “It was the first time they had done it,” says Bo. “The two brothers Tae and Yung pulled it off with all my requests. Good people and a great job.”

Diving into the fitout, Bo installed the shelves and electrical system himself, with help from Brad at Whitcroft IT who supplied knowledge along with the Victron components and 300Ah lithium battery. Three-colour dimmable lighting helps find things at night, while a Rockarmor 3000W inverter (with external display) helps power any high current devices. Bo has fitted an ice making dual-door 95L Gecko fridge (negating the need for the extra weight of a fridge slide), a full slide-out pantry, plus a slide-out prep table for the gas cooker.

Mode 4×4 canopy

Being of a composite design, the Mode 4×4 canopy is made up of an aluminium supporting structure to which lightweight composite panels are bonded, much like the construction of caravans from parent company Zone RV.

This means there are some limitations to where loads can be applied. The maximum internal load carrying is 350kg, with a dynamic weight of 150kg being allowed on the roof (350kg static). This drops to 110kg with one spare wheel bolted to the rear, and 75kg should you require two spares, or jerry cans etc. of a similar weight to a spare wheel.

In Bo’s case, there’s minimal weight stored up top with his fishing gear, solar panel and awning currently installed. With the current 35-inch tyre and billet bead-lock spare wheel, jerry can and ladder mounted on the back wall, this would make any more roof-mounted accessories an exercise in weight management.

Upgraded suspension

Suspension-wise, the Raptor comes standard with trick Fox Racing live valve shocks, and coil springs on all four corners.

These are electronically controlled 2.5-inch internal bypass shocks with in-cab mode selection. One very cool feature is the Ford software controls damping on the rear shocks to resist squatting on heavy acceleration. Having the GVM approaching redline was enough reason for Bo to add in the extra support of bellow-type airbags to assist with heavier canopy loads, or when towing, while also upgrading to G.O.A.T. Offroad front upper control arms and two-inch lifted front springs.

Kris, Cody and the team at Precision Offroad 4×4 in Wangara carried out the work including the wheel fitting. “They also re-programmed the suspension height in the computer so all the Ford sensors worked correctly with the upgrades, including the height of the front lights for oncoming drivers as well as the shocks sensing the correct ride height of the vehicle,” Bo says.

Engine upgrades

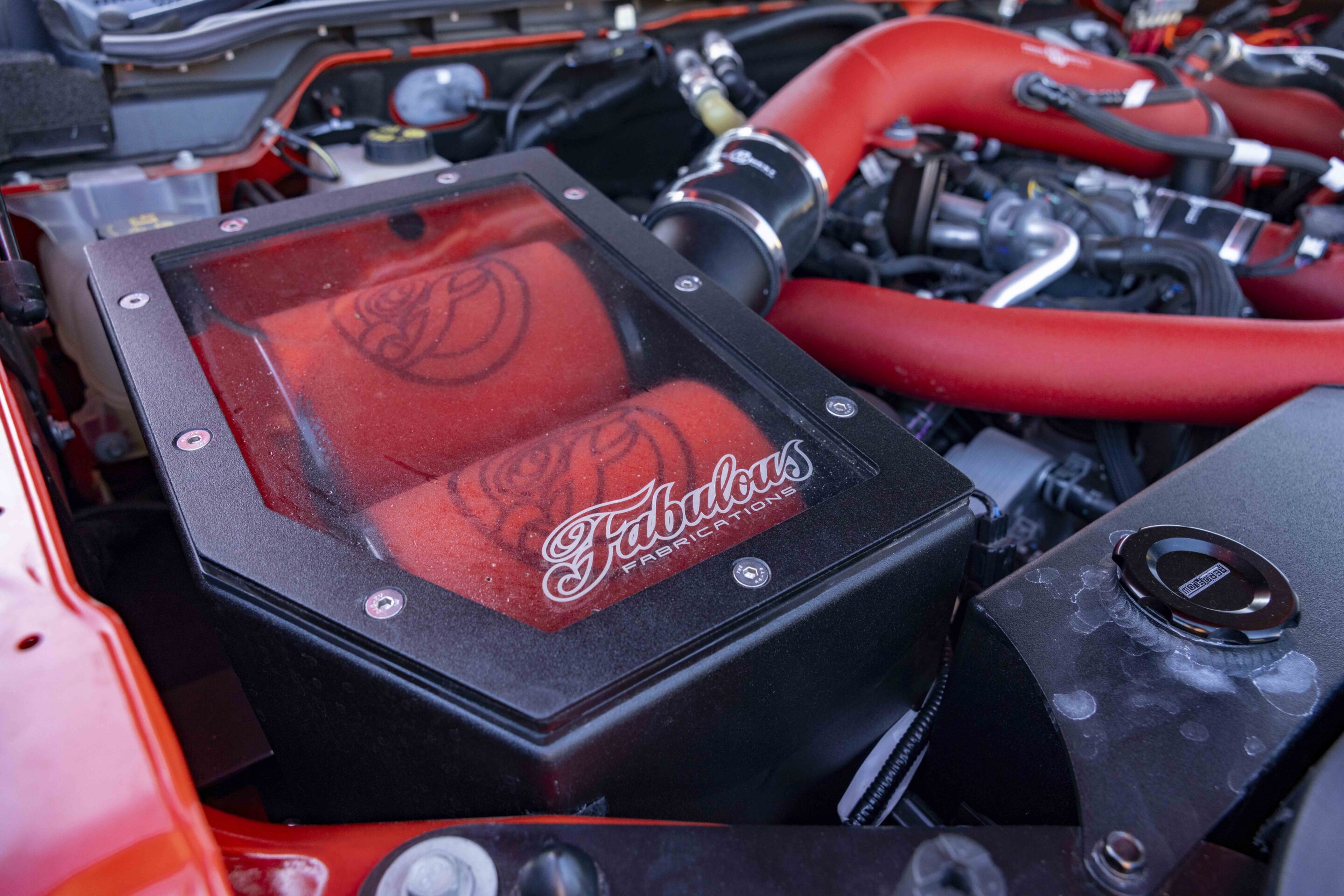

To keep things moving at an acceptable pace, Ford’s petrol-fed EcoBoost V6 twin-turbo powerplant provides the mumbo up front, driving through a 10-speed auto ’box, however Bo found a few items in need of attention.

“I installed a set of Process West turbo induction and intercooler piping as I did not like the way the Ford rubber hoses flexed and distorted under load,” he says. These were joined by an aftermarket windscreen washer reservoir, and then further modified to allow the fitment of the hard pipes.

Fresh air comes from a Safari Armax snorkel piped into the Fabulous Fabrications twin foam filter airbox. Out of the factory the Raptor can change its exhaust note at the touch of a button, so little was done to the exhaust other than a pair of bolt-on four-inch dual tailpipes. An initial tune yielded 480hp (397hp standard) and 725Nm (583Nm), however final fettling is due to be carried out after a longer run-in period. “I have heard of all sorts of things going wrong with the Raptors, but touch wood so far I have had no issues at all,” Bo says.

Rounding out the under-bonnet mods, Bo says, “I extended the breathers from the gearbox, front, centre, and rear diffs and the winch to just under the bonnet line. For the other small jobs I must thank a good friend Tim Gunn (Sik Em Wrex Racing). He’s my go to person for odd jobs as it’s done once and done correctly.”

Interior tech and comfort

Being the top-of-the-line offering from Ford, you’d expect the cabin to be a great place to be, and you’d be right, with lots of leather and race-style seats, plus more infotainment than most would need, it really does present as good-to-go. Bo set about further enhancing the interior and slotted in a Stedi light switch pod above the central screen, which also provides an access point for his GME 370C UHF radio.

Replacing the now redundant rear-vision mirror is a triple camera system monitor. This reveals front, rear and in-cabin views, while recording and allowing playback all from the one unit.

Verdict

After taking the path far less travelled and building such an outstanding level of tourer, Bo is in the final stages of his overall plan. “I’m building a small pop-top caravan of 1800kg that I am working on now. It’s an old 2004 Coromal SEKA 535 XC Pioneer built in Perth and is fully off-road capable.

The trip is to last for a number of years if possible, [so] I’m going to take my time and spend the majority of my retirement on the road seeing sights, travelling off-grid and meeting some awesome people.”

Keep an eye out for his rig as he makes his way around our map, and if you can catch him, say G’day.

Isuzu UK has announced pricing for its upcoming D-MAX EV, which will start from £59,995. That works out to around $117,000 AUD before on-road costs.

First deliveries in the UK are expected in March 2026, following an official launch in February. However, there’s been no confirmation yet for an Australian release.

Revealed at the 2025 Commercial Vehicle Show in Birmingham, the D-MAX EV will run a 140kW dual-motor drivetrain powered by a 66.9kWh battery. Three versions will be offered in the UK. The entry-level eDL40 comes in an extended cab configuration at £59,995 and a double cab version at £60,995. The top-spec eV-Cross double cab comes in at £62,495. All models feature a full-time 4WD system.

The eDL40 models come with chrome styling, an eight-inch infotainment screen, a seven-inch driver display, heated front seats, Bi-LED headlights, dual-zone climate control, leather upholstery, parking sensors front and rear, and a six-speaker audio system. The eV-Cross builds on that with dark grey trim, a larger nine-inch screen, auto-dimming rear-view mirror, and an upgraded eight-speaker sound system.

Despite no official word from Isuzu Ute Australia, the timing of the UK launch and the shared platform could suggest a late 2026 or early 2027 arrival here. Australian pricing would likely start north of $110,000 drive-away if based on straight conversions, though final figures will depend on local specs and taxes. Whether that price point can be justified will come down to how it performs in the real world – especially when it comes to range, charging and off-road durability.

With full towing capacity, a one-tonne tray, and proper 4WD, the D-Max EV is shaping up as one of the first electric utes built for work and play, and if it holds up to Isuzu’s reputation, it could give fleets and remote area operators a real EV option. Pre-sales in the UK open later this year, with fleet demonstrators arriving first.

The D-MAX EV will offer a one-tonne payload, 3.5-tonne towing capacity.

If you’re anything like me and drive an older 4×4, there’s a fair chance you’ve caught yourself talking to it.

Sometimes, an ageing rig just needs a bit of gentle encouragement to crest the next hill or crawl through a tricky section of track – maybe a quiet “come on, girl” and a reassuring pat on the dash to get her through. When this happens, the only reply I want to hear is the engine picking up revs as we clear the hill and power on. I don’t need a car to talk back – but these days, many new vehicles do exactly that, and not always in a good way!

Modern cars are constantly nagging the driver with safety warnings, speed alerts, traffic updates and all sorts of unnecessary chatter. Some even feel the need to tell you when there’s a curve ahead or a lane merging – things you’d already notice if you were looking out the windscreen instead of glancing down to see what all the chimes are about. One car I drove recently even displayed conversation prompts on the multimedia screen, suggesting topics to discuss with the car!

Thankfully, I can drown most of it out by turning up the radio – but I really shouldn’t have to.

The crazy thing is, all of these so-called safety systems are actually distracting the driver – encouraging you to take your eyes off the road to respond to prompts and warnings. Road-safety pundits love to blame mobile phones and passengers for driver distraction, but increasingly, it’s the vehicles themselves that are drawing attention away from what really matters.

And the irony? These same safety advocates are the ones pushing for these intrusive systems so manufacturers can tick the boxes needed for a five-star safety rating. When is enough, enough? Of course, the response is always the same: “Enough is enough when there are no more road accidents.” But that’s an impossible target – one that will never be achieved.

In the meantime, we’re stuck with technology that, ironically, only increases driver distraction under the guise of improving safety.

Chery’s first dual-cab ute for Australia is starting to take shape, with design patent images released earlier this year offering the clearest look yet at what’s likely to become the Chinese brand’s inaugural offering in the segment.

The renderings out of Argentina revealed a squared-off body with chunky proportions, upright headlights, and a practical rear step built into the bumper.

This vehicle is believed to be the larger, ladder-frame model currently in development for international markets. The smaller Himla ute shown in China won’t be sold here – instead, we’re expected to get a tougher platform aimed at buyers who need proper off-road capability, solid towing figures and real-world payload. The design sketches suggest something closer in size and stance to the HiLux or Ranger than a lifestyle crossover.

Adding further weight to the off-road focus is the Chery KP11 concept recently previewed in China – a rugged, body-on-frame 4×4 with aggressive styling and serious trail gear. While not confirmed as the production model, the KP11 gives a clear idea of the direction Chery is taking: a ute built to handle rough terrain and tough jobs, rather than just urban driving.

Built on a separate chassis, the new Chery ute is likely to offer a braked towing capacity of up to 3.5 tonnes, with a payload around the one-tonne mark. Suspension is expected to follow a familiar formula: independent up front with either a leaf or multi-link rear depending on spec. A rear diff lock, low-range gearing and other off-road essentials may also be part of the package, at least in upper trims.

Powertrain details haven’t been locked in, but the standout rumour is a diesel-based plug-in hybrid setup. If it eventuates, it would be a segment-first – a PHEV designed not just for city economy, but for regional touring and towing as well. Diesel’s long-range efficiency, paired with the low-speed benefits of electric torque, could make for a compelling combination, especially in a market where dual-cabs regularly double as family haulers and remote travel rigs.

A global unveiling is likely sometime in 2025, but the Australian launch isn’t expected until 2026. Final specs, badging and pricing remain under wraps for now.