Just rolled a shiny new 4×4 off the showroom floor and keen to hit the tracks?

Hate to break it to you, but spend enough time off-road or in the scrub and you’re bound to scrape something – and that new-car shine won’t last long. Here are a few products that’ll help keep your 4×4 looking sharp – and moving – when the going gets rough.

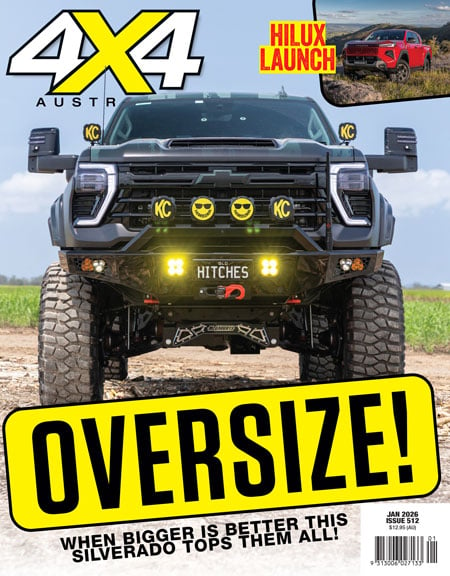

One of the first upgrades most 4×4 owners make – whether the rig’s brand new or an old favourite – is fitting a bullbar or replacement front bumper. For some, it’s all about the look. For others, it’s a necessity, with the bullbar ready to do the job it was designed for: protecting the front end when things go sideways.

What does a bullbar actually do? A bullbar is designed to protect vital mechanical components in the event of an animal strike or frontal impact. Its primary role is to shield the cooling system and front-end hardware, helping ensure the vehicle remains drivable so you can safely reach your destination. A secondary benefit is the protection it offers to body panels and headlights, keeping damage to a minimum and your lights operational.

To do the job properly, a bullbar needs hoops or structural elements that rise above the main crossbar to at least bonnet height, protecting the area directly behind the grille – where the radiator and other critical components live. Hoopless bars or anything that doesn’t offer this level of protection aren’t true bullbars and shouldn’t be labelled as such.

That’s not to say hoopless bars or metal bumper replacements don’t have their place. They offer more protection than the standard plastic bumper, usually provide better clearance for off-road driving, and give you a solid platform to mount a winch, driving lights or antennas. But let’s be clear – they are not bullbars.

Bullbars are just one piece of the puzzle when it comes to protecting your 4×4 off-road. While they’re primarily there to safeguard vital mechanical components, a complete protection setup should also include steel side steps or rock sliders, underbody protection plates, rear bumpers and side rails. These additions help defend against the inevitable knocks from rocks, ruts, trees and scrub out on the tracks – essential insurance for any rig that sees regular off-road use.

JUMP AHEAD

- Bullbars: Front protection

- Brush bars: Guard the sides

- Rock sliders and steps

- Underbody plates

- Rear bumpers

- Paint protection

Bullbars: Front protection

Bullbars are traditionally made from steel, but they’re also available in aluminium or even plastic composite materials.

Steel is the strongest option, but it’s also the heaviest – and that extra weight sits forward of the front wheels, putting added strain on the front suspension, especially if you’re also running a winch.

Aluminium bars are much lighter than steel, but being a softer material, they’re more prone to bending or damage in a serious impact. They’ll still do the job of protecting critical components, but the bar itself is more likely to suffer irreparable damage. Aluminium bullbars also tend to be more expensive than their steel counterparts.

Plastic or composite bullbars are softer and lighter again, but often have the advantage of flexing on impact and, in some cases, bend back into their original shape after an animal strike. Their flexibility also makes them more pedestrian-friendly, helping to reduce injury in the event of a collision with a person.

Because of their lighter weight and improved pedestrian safety, many fleet operators opt for composite bars. Despite their flexibility, they can still accommodate essential accessories like winches and driving lights.

Pedestrian safety is an increasingly important factor in the design of modern frontal protection. The complex safety systems built into today’s vehicles – from crumple zones to radar sensors – present ongoing challenges for bullbar manufacturers, who must balance compliance with urban safety standards while still delivering the rugged protection needed by drivers in the bush.

Just as new vehicles must meet strict safety standards, so too must the accessories fitted to them. Anything mounted to the front of the vehicle – including bullbars – must not interfere with the operation of factory safety systems like airbags, radar, or autonomous emergency braking.

Forward-facing cameras, radar units, sensors and even active bonnets – designed to reduce pedestrian injury – all need to function exactly as they did from factory. As these safety systems evolve, they present ongoing challenges for bullbar manufacturers. However, products from reputable suppliers are engineered to meet ADR requirements and won’t interfere with these systems. It’s always worth confirming compatibility with your supplier before making a purchase.

Brush bars: Guard the sides

Side bars – often called brush bars – connect to the upper hoops of the bullbar and run back to the chassis, usually tying in at the side steps or directly to the vehicle’s frame. Their main role is to brace the bullbar against impact and prevent it from being pushed rearward during a collision.

Brush bars also help protect the front guards and flares from damage when pushing through trees, thick scrub or tackling rocky terrain at extreme angles. They’re typically made from tubular steel for strength and durability.

Rock sliders and steps

The factory side steps fitted to most new 4x4s are exactly that – steps.

Usually made from plastic or light alloy and mounted to the body, they’re not built for punishment. Consider them consumables, as they’ll likely bend or snap off after the first decent scrape on a rock or erosion mound. They offer little to no real protection for your vehicle’s sills or lower panels.

For real protection, you need steel or heavy-gauge alloy rails mounted to the chassis – not the body. Proper rock sliders are built tough enough to absorb impacts and scrape over rocks or obstacles without transferring damage to the vehicle’s body.

If your rock sliders also need to function as side steps, look for a design that’s wide enough to comfortably fit a boot and features a grippy top surface to prevent slipping. It’s also important to check that they’re compatible with side rails, especially if you plan to connect them to a bullbar.

Heavy-duty rock sliders are another accessory coming under scrutiny from evolving safety regulations, as their fitment can affect the operation of side airbags and other integrated safety systems. It’s essential to ensure any sliders you choose are designed to work with your vehicle’s factory safety features.

Underbody plates

Before moving past the front half of the vehicle, it’s worth taking a look underneath.

Most modern 4x4s come with a basic tray or shield that extends from below the radiator to somewhere near the sump. These are often made from plastic or composite materials, though some manufacturers use thin pressed metal. While they help guide airflow and keep water out of the engine bay, even the metal versions offer little real protection from rocks, ruts or track impacts. Once again, the solution is to replace these factory covers with heavy-duty steel or aluminium plates.

Scraping the engine sump or transmission pan over a rock can cause serious damage – and in the worst-case scenario, punch a hole that leaves your vehicle stranded. Protecting these vital components is essential, and that’s where properly fitted metal underbody plates come in.

As with bullbars and sliders, aluminium is lighter than steel but usually more expensive. To match the strength of a steel plate, you’ll need a thicker aluminium one – but even then, it’ll typically weigh less than a thinner stamped steel equivalent. Steel plates are more likely to bend under heavy impact but can often be hammered back into shape. Thicker aluminium plates may resist bending, but they’re more prone to cracking or splitting if struck hard. Stainless steel is also growing in popularity for underbody protection, offering corrosion resistance and solid durability.

In addition to protecting the engine and transmission pans, it’s important to safeguard any other vulnerable components under the vehicle. Low-hanging lines or wiring should be routed high and out of harm’s way. Some manufacturers now offer specific metal guards for items like shock absorbers, ABS sensors and other exposed parts underneath – all of which can be damaged on rough terrain.

The differential can also benefit from added protection – whether it’s a guard over the pinion yoke or a reinforced cover at the rear.

It’s also worth noting that any increase in ground clearance – whether from taller suspension or upsized tyres – will lift your rig higher off the ground and help reduce the chances of scraping on rocks or bottoming out on rough tracks.

Rear bumpers

While it’s pretty rare – though not impossible – to cop an animal strike on the rear of your 4×4, the back end still needs protection.

The most vulnerable area is the rear corners, which can easily get hung up or scraped on rocks, ledges or steep exits. On many newer – and even some older – 4x4s, these corners sit low and are made from plastic, making them prone to cracking or tearing off. GU Patrol wagons, for example, have long been known for busting up their rear corners on the tracks.

A well-designed steel rear bumper will taper up at the corners to improve clearance and keep them out of harm’s way. The best setups also incorporate rated recovery points, a tow hitch and optional spare wheel carriers. Quality designs wrap around the rear corners of the body, protecting the lower edges of the rear quarter panels from scrapes and impacts. Even a well-made tow bar can offer some protection under the back end without the need for a full replacement bumper.

Paint protection

It’s inevitable – spend enough time driving your 4×4 through the bush and sooner or later you’ll scrape it against a branch or stick and mark that shiny new paintwork.

Some folks wear bush pinstripes as a badge of honour, while others nearly shed a tear at the first sign of damage. If you fall into the latter camp, don’t worry – there are plenty of ways to protect your vehicle’s paintwork.

Paint Protection Film (PPF) is one of the most popular and effective options. It’s typically a clear wrap that can cover the entire vehicle or just high-risk areas like the front end and along the sides. Some PPF products are even marketed as “self-healing” – meaning light scratches can disappear with the application of a little heat, restoring the film’s protective finish.

For heavier-duty protection, there are physical shields that attach to the bodywork using magnets or adhesive, offering full coverage over vulnerable panels. Another popular option is ceramic paint coating – a liquid-applied layer that bonds to the paint to help protect against dirt, UV damage and minor contaminants while preserving that glossy finish.

Or you can just embrace it – your 4×4 takes you to incredible places, and a few scratches and dents are part of the story. After all, it’s only the first one that really hurts… after that, you stop worrying and get on with the adventure.

We recommend

-

Advice

Advice8 essential tips for a safe outback adventure in Australia

Stay safe on your next outback adventure with these eight practical tips

-

Opinion

OpinionAll the gear and no idea: Why plenty of tourers aren’t prepared for the outback

A sat phone alone won’t make you ready for remote travel

-

Gear

GearHow to prepare for a 4x4 road trip in Australia

Planning a 4x4 road trip in Australia? Here’s a guide on how to prepare to avoid disaster.