For most of us who enjoy camping and four-wheel drive touring, it’s essential to have a portable fridge.

To keep the fridge running while the vehicle is parked, you need plenty of reserve battery power. However, for many people, adequate electrical capacity is not just a convenience that helps keep your beer and food cool. It is also an essential requirement for work as it powers equipment such as safety lights and radios when a vehicle is stationary.

So a dual battery system is a must. There are a few ways the second battery can be wired into the vehicle, depending on its intended use and the system flexibility required. But no matter what, the second battery must be installed and wired – in the engine bay, the passenger compartment or load area – so that it can be isolated and doesn’t flatten the vehicle’s starter battery.

The final requirement of a dual battery system is for the second (or accessory) battery to be easily charged by the vehicle when you’re driving or the engine is running. This will ensure it’s charged and eady to use when you arrive at the next campsite or job.

JUMP AHEAD

- Installing a second battery

- What battery does what?

- Keeping them charged

- Automatic solenoid switching

- Manual four-way switching

- Electronic battery management systems

- Taking charge

- Portable battery packs

- Dual battery systems tested

Installing a second battery

Most vehicles are built with one battery, so installing a second battery to power requires extra hardware – this usually includes a strong fabricated steel tray fitted in the vehicle’s engine bay.

To carry 15kg (or more) of battery in tough off-road conditions, the tray must be heavy-duty to prevent vibrations – especially vibrations that come via corrugations – from destroying it.

Many Aussie equipment manufacturers such as ARB, TJM, and Piranha design and manufacture trays for popular 4x4s. These companies have extensive experience, and they make tough and durable products that place the battery’s weight into strong sections of the vehicle body shell to reduce the chance of sheet metal cracking or tearing. Most will use factory-provided installation points and several stays to provide plenty of stability and support.

However, many vehicles – especially more recent models – don’t have spare room in the engine bay, so the second battery must be located elsewhere in the vehicle, such as in or under a load tray or in the passenger compartment. This means you need to pay extra attention to the wiring and battery type chosen.

The fitment of an accessory battery tray can often be achieved by a competent handyman, although vehicle components – such as a power steering reservoir or an air-conditioner pipe – may require tweaking or relocation to provide space for a second battery tray.

No matter what, batteries hate heat, so batteries should be installed as far away as possible from hot engine components; preferably on the cold side of the engine, opposite the exhaust.

No vehicle will endure a 15kg battery hanging from an inner mudguard with two small bolts or screws. Fasteners must be adequately sized and have large washers to spread the load across the panel work (such as an inner guard). You should also regularly inspect the area for cracks or loosening.

Damage of this type, usually resulting from cheap, poor quality products have wrecked many outback treks.

What battery does what?

In most dual-battery installations, the second battery’s task is to power the accessories (such as fridges), and it’s for this reason that a deep-cycle or dual-purpose battery is often installed.

The vehicle’s starting battery and its wiring remain largely unmodified for starting and powering the vehicle and its equipment (such as radios and interior lights), while the second battery happily powers the fridge when the vehicle is parked.

Because of the lack of space in some engine bays, the second battery may have to be physically smaller than the vehicle’s original – too small to be useful for powering a fridge.

The genuine accessory dual battery system for the Mazda BT-50 mounts the auxilliary battery in the tray and uses a Redarc solenoid in the engine bay for charging managment.

Situations like this require some lateral thinking from the installer or operator; the aftermarket battery tray may need to be configured to carry a small back-up/ starting battery, with the vehicle’s original battery (or a replacement dual-purpose/deepcycle battery installed on the original tray) powering the fridge.

Vehicles with factory-fit twin batteries – such as many diesel Land Cruisers, Prados and later D22 Nissans – can be easily re-configured to have a starter and accessory battery, too, rather than twin starters. Some people wrongly believe they’re looking at a factory-fitted, trek-ready dual-battery system when they lift the bonnet of these vehicles. They’re not. But the original wiring of these vehicles can usually be easily reconfigured to accommodate a proper dual-battery system.

Many vehicles’ standard battery positions will house a larger-than-standard battery. Kilo for kilo, a larger lead-acid battery will provide power for longer than a smaller one, and a vehicle’s factory battery location is often stronger than even the best aftermarket tray.

Keeping them charged

At its simplest, a second battery can be wired into the vehicle with some appropriately sized wire (and a circuit breaker or fuse for safety) and a simple high-amperage on/off switch.

This allows the second battery to be charged while you’re driving, and disconnected (isolated) when it’s time to set up camp and operate the fridge and camp lights – without running the vehicle’s main battery flat.

The next day, after the vehicle is started, the switch connects the second battery to the vehicle’s electrical system, allowing it to be charged from the alternator. This provides a dead-set simple and reliable way of doing things and has worked for generations of outback travellers.

But there are drawbacks to this method, the biggest being its susceptibility to operator error: the driver needs to remember to flick the switch to either isolate or charge the accessory battery. That’s no biggie if you have the discipline to lift the bonnet to check oil and fluid levels each morning – as you should!

Another drawback is that the entertainment system and interior lights continue to operate from the main battery, which exposes it to the risk of being run flat with excess or careless use.

Automatic solenoid switching

Wired to the vehicle’s ignition system, a solenoid will automatically disconnect the accessory battery when the ignition is turned off. It reconnects the second battery to the vehicle’s main battery (to allow charging) when the engine is running. This way, you don’t need to remember to switch-out the accessory battery at each stop-over, and you won’t risk flattening both batteries.

4×4-grade solenoids generally have higher-amperage wiring to the second battery (often of a similar size to the vehicle’s starter cables – in fact, many solenoids used for dual-battery tasks are the same tech as some older-vehicle starting solenoids), so there’s little risk of frying wires. The second battery can be used to jumpstart the vehicle, if required, by overriding the solenoid.

One minor drawback of this system – at its most simple – is the accessory battery is switched on whenever the ignition is on, including during engine cranking, and this may allow a seriously flat accessory battery to pull down voltages at the ignition coil or engine control unit to a level below the point at which they can fire the motor.

One way around this problem is to wire the solenoid to the generator light circuit (or a simple electronic timer circuit), so that it doesn’t connect the accessory battery – and therefore pull down system voltage – until after the engine has come to life.

Manual four-way switching

A four-way switch allows the vehicle’s first or second battery to perform either of two roles: starting the vehicle, or powering equipment while totally isolating the other battery. That’s great if at camp you wish to operate your vehicle’s radio or other accessories, without risking flattening both batteries.

As with the simple switch system, this full-manual system relies on the driver. But it offers the extra flexibility of allowing the fridge and other accessories to be operated with just one battery in the vehicle – not always possible with other layouts – which means part-time travellers don’t have to lumber around town all year with a battery doing nothing on board.

Rotating the switch to the position where the batteries are connected (1+2 or A+B) allows both batteries to be charged. This paralleling of the batteries also provides plenty of grunt for operating a winch – an important consideration for many people.

Electronic battery management systems

Electronic battery management systems have been available for a while, with varying levels of sophistication and flexibility. All provide automatic isolation and charging of the accessory battery – in that regard, they operate like a simple solenoid or relay. Some of these systems claim priority charging of the vehicle starting battery.

However, this is often not true for all systems. Instead, the second battery remains switched-out until the system voltage exceeds a pre-set level; usually just after the vehicle fires into life and the alternator pushes system voltage above 14V.

Some electronic battery management systems provide extra useable power capacity at camp by allowing the accessories to be powered from the vehicle starting battery for a while before automatically switching to the second/ accessory battery when the starting battery reaches a partially discharged but safe-for-starting level.

As previously mentioned, vehicle equipment such as entertainment systems, interior lights and central locking continue to be powered by the vehicle’s own battery, so accessory battery isolation won’t prevent these accessories from draining your vehicle’s main battery.

The adoption by most vehicle manufacturers of variable voltage charging (to help vehicle emission targets) in the past decade means that a little black box is almost essential for second battery charging. That’s because, for a variety of reasons, a second battery usually can’t be effectively charged by simple ‘old-school’ linking in parallel with the vehicle’s main battery.

Batteries in caravans and camper trailers may also need electronic assistance. Their distance from the charge source means actual voltage available (which reduces over distance, like water pressure does in a long garden hose) may be too low to effectively charge the batteries for best performance or life.

As all batteries rely on the push of a higher voltage (typically 14-14.4V from a vehicle alternator) to be charged, these batteries may suffer at the end of a long cable run, requiring the step-up – and constant – voltage that’s provided by a DC/DC charger.

Taking charge

No matter what system is being used, charging time and rate needs to be factored into the setting-up of a 4×4 vehicle or camper/caravan battery bank. Batteries take time to charge and don’t charge in a linear manner.

A well-depleted (flat) battery will accept lots of current at first but far less current as it approaches full charge. Think of the 80/20 guideline – a battery will be 80 per cent charged in 20 per cent of the time it takes to be fully charged. The last 20 per cent of battery capacity takes a lot longer to achieve.

The typical touring day of six to eight hours’ driving (and therefore charging) time may not be enough to fully charge a depleted battery bank. Having plenty of charging capacity – for example, a 200A alternator in your vehicle – will not charge things any quicker than an 80A unit if the battery (or batteries) only takes 40A.

A trick to reduce charging time is to use multiple smaller-capacity batteries in parallel. They will charge in less time (of course, while drawing more current) than one large battery of the same capacity (e.g. two 50AH batteries versus one 100AH).

When relying on accessory power in remote areas, this is an important consideration, as is the fact that multiple batteries can be separated due to damage, or loaned for other uses – getting a stranded vehicle running, for example.

Portable battery packs

Portable battery packs are another way of powering accessories. Many vehicles simply aren’t used often enough for touring to justify a permanently installed accessory battery, or they have insufficient room under the bonnet for a traditional second battery installation.

Portable power packs are available in several shapes and sizes (and, of course, levels of quality). The better ones exceed the performance of a vehicle-mounted accessory battery, but in a relatively easy-to-move package that can be removed from the vehicle (or used elsewhere) when it’s not required.

That way, you can keep a fridge running at camp while you’re out exploring in your 4×4, or you (and your mates) can use them in other vehicles. They are also handy around the home or garage.

Dual battery systems tested

We test the latest management systems, mounts, and batteries that won’t leave you in the middle of the outback with a slab of warm coldies.

The principle behind a management system is that it charges an auxiliary battery when power is available and disconnects, or ‘unlinks’, when voltage reaches a predetermined level to avoid killing your main cell. Options are full manual, voltage-sensitive relays (VSR) and programmed relays.

Regarding batteries, the most common are flooded lead-acid (wet), absorbent glass mat (AGM), and lithium iron phosphate (LiFePO4). The former two are available in standard or deep cycle. Deep cycles are generally used as auxiliaries, as conventional batteries can be damaged if fully discharged.

Lithium offers premium performance but at significant cost and should not be mounted in an engine compartment. Regardless of type, a battery needs proper care to maximise its lifespan.

Our install platforms were a 2015 JK and Gen III Toyota Tacoma, and we selected systems from National Luna, TJM’s Intelligent Battery Systems (IBS), Redarc, CTEK, and Blue Sea. Mounting trays are from Mountain Off-Road Enterprises and Off-Grid Engineering which offer turnkey systems.

When the nearest roadhouse is 200 kilometres away, you can’t cut corners under the bonnet when it comes to battery selection. For this review we sourced cells from Odyssey (Extreme Series) and Optima (Red Top and Yellow Top deep cycle). While a few management systems are nearly bolt-in, some require a more technical hand.

To evaluate each in a controlled environment, we set up a bench test. Current was supplied by an MCP DC power supply, and load was provided via a 2000-watt inverter powering an ARB fridge-freezer, AC battery charger set to 6amp output, and our photo studio lighting. Voltage and amperage, along with solar input, were recorded with a Powerwerx DC power analyser.

Each system was run for several hours to experience multiple charge/discharge cycles while we evaluated its attributes: link/unlink voltage, over and undercurrent cutoff, under/overcurrent alarms, etc. Goal Zero solar panels provided power to units that accommodated wind or solar, and proper function was confirmed.

Other considerations were manual-link options, single-battery function, IP ratings (moisture and contaminant intrusion), completeness of kit, available accessories, ease of operation, and quality of instructions.

Newer vehicles have variable-output alternators (VOA) which reduce voltage based on a variety of conditions to reduce parasitic drag on the engine. Two systems reviewed accommodate this technology.

Lastly, winches can draw significant amperage during heavy pulls, and a single battery and alternator will not keep up with demand. With the exception of one system, an old-school manual switch would be required to draw this level of current from both banks.

Without further ado, we present some of the best dual-battery systems on the market … we hope you get a charge out of them.

Redarc BCDC1225D charger

Redarc has 40 years of experience providing mobile electrical components for the Australian outback. The award-winning BCD1225D offers an array of advanced options including multi-phase charging algorithms and solar/wind input compatibility, and it plays well with VOAs. It is sold à la carte, so you’ll need to source cable, lugs, fuse kits and hardware. We added their remote in-cab dual-voltage gauge.

During installation we wired it for profile ‘A’, specific to AGM batteries. Each algorithm has a defined charge cycle (boost, absorption and float) to ensure maximum service from your batteries. A ‘test mode’ evaluates input/output levels and presence of an auxiliary battery, and error codes are identified via a series of LED lights.

The BCDC1225D features an MPPT regulator and leads for solar input, and their unique Green Power Priority directs that energy to the house battery before charging the main. It can be mounted in the engine bay or on the chassis, but should be kept away from high-heat sources, as its thermal protection kicks in at 79.5C.

Unfortunately, its 25amp capacity does not allow jumping a dead start battery and there is no manual link. We would suggest an auxiliary Perko-style switch to connect both batteries for winching or jumping the main.

Instructions are excellent but set-up is a bit technical, and if you have a VOA you will need to locate your ignition circuit. During testing the BDC1225D performed flawlessly; it kept both batteries healthy and Green Power Priority managed solar input as intended. When the dust settled, the Redarc headed home with our High-Tech Award.

Pros

- Water and dustproof

- Multi-stage charging

- Built-in solar controller

- VOA compatible

Cons

- Low amperage rating

- Lacks manual link

- Cost

CTEK D250SE and Smartpass 120S

The CTEK D250SE also lands in the high-tech category. It will service an auxiliary bank up to 300amp/h and all 12-volt battery types. There are separate charging algorithms for AGM and lithium cells, and selection is made during the installation of wiring.

It efficiently manages solar input via an internal MPPT regulator, and when the auxiliary bank is topped off power is directed to the primary battery. A unique feature of the D250SE is its thermal sensor, which signals the mother ship if temperatures reach damaging levels. It is IP65 rated for dust and water protection. The 20amp maximum does not accommodate a manual link for jump starting, but combined with CTEK’s Smartpass 120S capacity rises to 140amp.

Installation in our 2018 Tacoma was simple, and the instruction booklet is excellent. These units mount side-by-side, so you’ll need to confirm you have the real estate available. We opted for the 250SE and will add the Smartpass if needed.

In the lab, the 250SE worked as intended, directing current from our solar panels to the house bank, then the start battery. This is a well-thought-out system and was in the running for the High-Tech award, falling short only due to its operating temperature limitations.

Pros

- Water and dustproof

- VOA compatible

- Built-in solar controller

- Dedicated charging algorithms

Cons

- Low maximum amperage

- Lacks voltage meter

- Limited operating temperature

- Cost

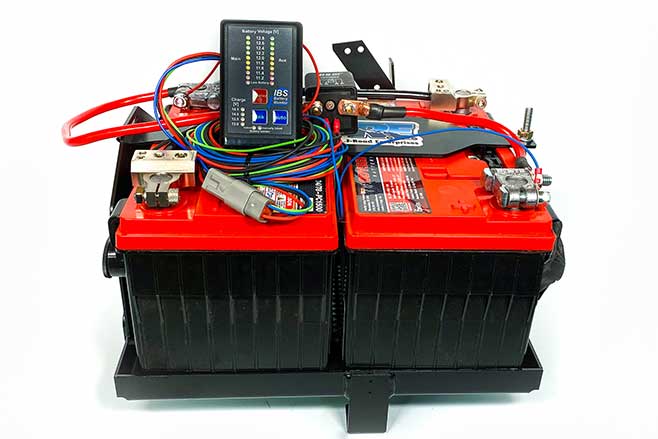

Intelligent Battery Systems IBS-DBS EM

IBS (Intelligent Battery Systems) was formed in 1996 after its founder Beat Wyss became stranded in Western Australia with a flat battery. Returning to Switzerland he developed the DBS, or Dual Battery System. This is a comprehensive kit, and includes all components needed for installation: solenoid, battery terminals, control panel, harness and cables.

This system allows for full control of functions, as well as monitoring battery voltages levels, from the driver’s seat. The bi-directional relay automatically closes the circuit when the main bank reaches 13.1 volts and opens at about 12.5 volts (as tested).

It allows single-battery operation via its ‘trailer recognition’ feature, has an audible over/under current alarm, and is compatible with all 12-volt cells – though it must be pre-programmed for LiFePO4s. Vehicles with VOAs will require their Mini ATO compensator or IBS’s new Dual Battery Manager.

Manual link-start is accessed from the control panel, and with a 200amp capacity (500amp surge) it will easily jump your main and assist with moderate winch loads. Mounting location should not be subjected to submersion, as this unit is not waterproof. On the bench, everything functioned as prescribed, installation was painless and instructions clear. This is a very functional product at an affordable price, and thus receives our Best Buy Award.

Pros

- Comprehensive kit

- In-cab control panel

- Simple installation

Cons

- Not waterproof

- Not VOA compatible

- Lacks solar regulator

National Luna Battery Manager

National Luna (NL) originally developed power options for solar-powered vaccine refrigerators for remote regions of Africa. The application was perfect for the overland crowd and NL has become a household name.

Similar to the IBS, it is a split charging system, all functions are monitored via a dash-mounted panel, and it does not accommodate variable output alternators. This is a comprehensive kit and includes everything needed for installation: terminals, lugs, fuses, hardware, harnesses and cables.

Shortly after startup the solenoid links both banks, and they stay linked until voltage drops below 12.7 volts, specifically after the engine is off and accessories are running. A dragstrip-style LED Christmas tree on the monitor keeps the user apprised of voltage levels and if there is a problem.

The ‘set’ and ‘on’ buttons perform several functions, including a timer override and manual linking. You can jump the main battery from the house unit if needed, but due to its 100amp fuse it is suggested you let charge levels equalize for a few minutes first. Also, if the auxiliary battery is removed the system will throw an error code unless you disconnect a ground wire.

Instructions are thorough and set-up was easy, but with an IP40 rating it should not be subjected to excessive water. Bench evaluation revealed flawless operation with the exception of the 11.4-volt failure alarm, which we did not test.

This is a nice kit and was easily in the running for our Best Buy Award, but its 85amp continuous-operation limit (400amp surge) held it back.

Pros

- Easy installation

- Comprehensive kit

- In-cab monitor

Cons

- Low amperage capacity

- Lacks solar regulator

- Not waterproof

- Lacks VOA compatibility

Off-Grid Engeering Mount and Blue Sea ML-ACR

We first viewed Off-Grid’s dual-battery system at an off-road event and were immediately impressed with the beautiful CNC-milled aluminium mounting bracket.

This comprehensive kit includes hardware, a plug-n-play braided harness, terminal ends, pre-cut cables, and Blue Sea ML-ACR isolator. Blue Sea, purveyors of battery management systems for the marine industry, has earned a stellar reputation and their products have made a natural crossover to overland applications.

The ML-ACR lacks fancy LED arrays, but it gets the job done with simplicity and rugged components. After starting the engine, the magnetic-latching relay links batteries when voltage reaches 13.5, then ‘unlatches’ if voltage drops to 12.75 for more than 30 seconds. If any battery exceeds 16.2 or drops below 9.6 volts, the system enters lockout mode to protect components.

Its 500amp capacity and manual link easily accommodate jump starting and extended winching operations. From the dash-mounted toggle you can manually link batteries, isolate banks or turn the system off, and a dial on the base unit allows you to latch or lockout the system. Its IP66 rating is best-in-class and it performed flawlessly in the lab.

Installing the mount required fabricating a riser plate, which we did, but they say their new design will be bolt-in.

The ML-ACR does not accommodate VOAs, so we substituted the Redarc on the Tacoma. But for non-VOA vehicles, the ML-ACR is one tough unit with the fortitude to take a beating. FYI, its new home will be on my ’82 Hilux.

Pros

- Best-in-class waterproof rating

- Best-in-class amperage rating

- Lifetime warranty

- High-quality construction

Cons

- Lacks solar regulator

- Lacks voltage meter

- Not VOA compatible

- Mount required fab work

Mountain Off-Road Jeep JK mount

If you only need a dual-battery tray, Mountain Off-Road offers a high-quality option for 2007-and-up Jeep JKs. Crafted from powder-coated 1/8-inch plate steel, it incorporates the OE attachment points and accommodates two Group 34 batteries.