From Cape York to the garage: ARB’s origin story

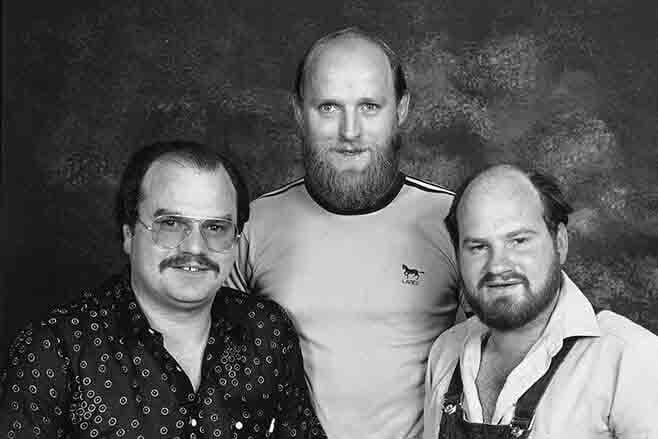

ARB was founded in 1975 after Anthony Ronald Brown (Tony) returned from a trip to Cape York in his Land Rover Series I.

Witnessing the punishment dished out by the rough roads and tracks of the time, he saw a clear need for stronger, more reliable accessories for 4×4 vehicles. Back home, he got to work in his garage, using a homemade pipe bender and a 130A stick welder to build roof racks and bullbars.

Within a year, Tony had moved into a small factory in Ringwood, Victoria, and hired his first employee, John van den Eynden. John would remain with the company until the 2020s, eventually managing ARB’s Thailand operation from its inception in 2006 until his retirement.

Around that time, Tony’s brother Roger joined the business, followed a few months later by their other brother, Andy. All three were hands-on and mechanically minded. As Andy recalled with a laugh, “I had a small workshop back then and we used to buy secondhand VW Beetles out of the Melbourne Trading Post on Thursday mornings, fix them up, give them a coat of paint and sell them on the weekend through The Age classifieds.”

Expansion, family ties and early milestones

By the time Andy joined his brothers in 1977, they had established their second dedicated factory in Ringwood.

Their first multi-unit order soon followed – 10 front bars with wheel carriers to suit VW Kombis, commissioned by Sunshine Campervans. In July that year, ARB Engineering was officially formed.

The 4×4 industry was still in its infancy back then, with Andy recalling, “You know, in the ’70s, one vehicle in 25 was a four-wheel drive. Now, nearly one in two vehicles on the road is a four-wheel drive!” As the market share of 4x4s has grown, so too has the industry – with ARB leading the charge, not just in Australia but around the world.

By 1978, with vehicles like the LandCruiser BJ40 and Nissan G60 gaining popularity among recreational four-wheel drivers, ARB had taken on the role of distributor for Old Man vanEmu (OME) shock absorbers (founded by John Chapman in 1976), along with Gabriel shocks, Lovell Springs and Cibie driving lights. These were soon joined by AVM free-wheeling hubs, Warn winches, Topkat canopies and later, Brahma canopies – all while ARB continued building an expanding range of roof racks, bullbars and ladders.

I was one of those aspiring recreational four-wheel drivers back then, and with a 47 Series LandCruiser to my name, I visited the ARB factory in search of a bullbar and roof rack – the beginning of a long association.

Engineering innovation and ASX listing

In 1981, with more than 20 staff on the books, Tony developed the upswept wing design for ARB bullbars – a feature that improved approach angles while preserving the renowned animal-strike protection. Today, that upswept profile is a hallmark of nearly every bullbar design around the world.

In 1986, after two more moves to larger premises and a distribution network that covered the country, ARB moved to its new, much improved headquarters at Croydon, Victoria and with more than 5000m² of work space they again increased production of their barwork. Around this time Tony stepped away from ARB, buying a cattle property in the Victorian High Country and leaving the day-to-day running of the burgeoning empire to Roger and Andy.

The following year was a big one with ARB buying the Roberts Diff Lock, remodelling and improving it, and launching it as the ARB Air Locker on both the Australian and the American markets where it became an immediate success. As well, the company designed and manufactured its own 12V air compressor to be used as a stand-alone compressor or in conjunction with its Air Locker.

That year culminated in ARB being listed on the Australian Securities Exchange (ASX) where it is still a major player. The following year I took over as Editor of 4X4 Australia and I was advised to buy some ARB shares. I wish I had!

In 1988 ARB took over OME after a bidding battle with its then nearest competitor, TJM. With that purchase ARB could boast a full suspension range of springs and shocks and associated hardware.

For many years OME shocks came out of the Monroe factory in South Australia, built more and more to ARB’s increasingly strict standards and the requirements of coil spring vehicles, which were led here in Australia by the Nissan GQ Patrol and quickly followed by the Toyota 80 Series LandCruiser. Yeah, we know the Range Rover had coil suspension first, but you could never say it was very popular or took the Australian 4×4 world by storm… as good as it was.

The Nitrocharger twin-tube shock has long been the mainstay of the OME range and with continual improvement to construction, shaft size, multi-disc compression valving, oils and nitrogen gas, it is still relevant today, offering great value-for-money and unequalled performance in its price range.

R&D, global growth and the Bilstein partnership

In 2015, Old Man Emu expanded its line-up with the introduction of the BP-51 range – high-performance, remote-canister, internal bypass shock absorbers that are user-adjustable and designed to deliver improved comfort and control on- and off-road.

Having just returned from a long outback run that included the Gunbarrel and Gary Highways, along with plenty of punishing tracks, in a BP-51-equipped 200 Series Cruiser, I can personally vouch for the quality of the ride – it stays composed and controlled even after hours of corrugations and through savage whoopty-doos.

Never one to stand still in the suspension game, ARB teamed up with globally respected shock absorber manufacturer Bilstein in 2022. Bilstein now manufactures the Nitrocharger Plus range, and ARB manufactures the MT64 and BP-51 in its Thailand factories. When news of the partnership first broke, it struck me as a perfect union of engineering expertise – a blend of technology and experience that few other shock or 4×4 accessory brands could hope to match. Strangely, ARB hasn’t made a bigger deal about it.

In a major step forward for its expanding camping gear range – which already includes roof-top tents and fridge/freezers – ARB launched the Earth Camper in Australia in 2023. Backed by over five years of design and development, the camper is built at ARB’s manufacturing facility in Thailand. While it hasn’t quite achieved the level of success or market penetration originally expected – Australia’s camper trailer market is fiercely competitive – the Earth Camper has now been launched in the USA, where it’s gaining momentum. With ARB’s ongoing focus on refinement and quality, both production and sales have ramped up.

Then there’s ARB’s OEM involvement, supplying 4×4 accessories to major vehicle manufacturers – most recently seen in the Ford Ranger line-up. When I asked Andy about the upcoming Ford Ranger Super Duty, due to arrive in Australia early next year, and whether ARB had any input, he was understandably tight-lipped. “I’m not sure what I can tell you here,” he said, “but I can say we have nothing to do with the suspension.”

While all this technical development was underway, ARB was also making significant moves on the manufacturing and distribution front.

A 50-year legacy – and what’s next for ARB

No manufacturing business thrives without a strong retail network, and in ARB’s early days, stores like Traction 4 in Sydney (owned by Norm Needham) and Northern 4WD in Melbourne (run by Rob Kay) set the benchmark others aimed for.

Fast forward to today and ARB boasts more than 70 retail outlets across Australia, supported by around 150 stockists and independent dealers nationwide – meaning you’re never too far from an ARB supplier, no matter where your travels take you.

With global demand on the rise, ARB established a manufacturing facility in Thailand in 2006 – a logical move given the presence of major Japanese ute and pickup factories in the region. What began as a 16,000m² operation has since expanded to a massive 96,000m², making it ARB’s largest production site worldwide. Today, the facility employs over 700 staff and houses more than 120 CNC machines cutting, bending and shaping components at scale.

That’s not to say ARB has turned its back on Australian manufacturing – far from it. Despite increasing challenges from government policy that often runs counter to public statements, ARB continues to produce a significant portion of its gear right here. From its Kilsyth facility in Melbourne, nearly all barwork for the Australian market is manufactured, along with every Air Locker differential and ARB air compressor sold globally. Over in Dandenong, a world-class distribution centre keeps products flowing to markets across the planet.

ARB’s canopies are built at its dedicated facility in New Zealand, while its rotomoulded products – including bullbars and fuel tanks – are manufactured at its factory in South Australia.

With the North American market booming, ARB now operates three major distribution centres in the USA – one on the west coast in Seattle, another on the east coast in Jacksonville, Florida, and a third in Texas, which also services South America. In 2023, ARB acquired a 49% stake in US-based Nacho Lights, followed in 2024 by strategic partnerships with 4WP (4 Wheel Parts) and Offroad Warehouse, giving ARB direct access to more than 70 4WD retail outlets across North America.

ARB’s European distribution hub is based in Prague, Czech Republic, supported by additional centres in the UK. In the Middle East, distribution is handled from the UAE.

All up, ARB distributes its products to more than 140 countries and directly employs over 2500 staff, with a further 700 working across its various partner companies. As the company marks its 50th anniversary this month, it’s also celebrating a strong presence on the ASX, with a current share price hovering around $30 and a market capitalisation of approximately $2.5 billion.

After a three-hour wander through ARB’s Kilsyth factory and new office complex, I asked Andy what the future holds following such a stellar 50-year run. His response was typically measured: “Well, I think we’ll be doing a bit of consolidation and working on making the things we do better, even more reliable – and keeping our costs down so our products offer even better value to our customers than they do now.”

That’s good news – but I couldn’t help feeling there was more going on behind the closed doors of the engineering department than Andy was letting on. Either way, the future looks bright for this proudly Aussie company. Like many others, I’m keen to see what ARB pulls out of the hat next as it continues to expand its global footprint in the 4×4 accessory game.

In the meantime, we should all be proud of ARB and the ground-breaking role it has played in not only rising to the top of the global four-wheel drive accessory market, but also paving the way for many other Australian 4×4 equipment manufacturers to follow.

It’s a remarkable legacy for a company that began in a backyard garage, sparked by the ideas and determination of one man, Tony Brown, and carried forward by the vision and commitment of his brothers, Roger and Andy Brown.

ARB timeline

| Year | Milestone |

|---|---|

| 1975 | Tony Brown starts building roof racks and bullbars in the family garage. |

| 1976 | First ARB factory (93m2) opens in Ringwood, Victoria. |

| 1986 | ARB moves into a new 5000m2 headquarters in Croydon. |

| 1987 | Acquires Roberts Diff Lock (Air Locker), develops 12V compressor, and lists on ASX. |

| 1988 | Acquires Old Man Emu (OME), expanding suspension range. |

| 1997 | Launches first airbag-compatible bullbar, crash-tested with Monash University. |

| 1998 | Begins designing and manufacturing canopies. |

| 1999 | Relocates to current Kilsyth HQ and factory. |

| 2003 | Acquires Kingsley Enterprises and Bushranger 4×4 Gear. |

| 2005 | Launches own line of 4×4 recovery gear. |

| 2006 | Opens 16,000m2 manufacturing facility in Thailand (now 96,000m2). |

| 2008 | Launches ARB fridge/freezer – future best-seller. |

| 2012 | Introduces Intensity LED driving lights. |

| 2014 | Establishes ARB Europe, acquires SmartBar, launches Ascent canopy. |

| 2015 | OME releases BP-51 bypass shock absorbers. |

| 2016 | ARB Middle East opens; Frontier polymer fuel tank launched. |

| 2017 | Opens global distribution centre in Dandenong. |

| 2019 | Establishes ARB New Zealand. |

| 2020 | Acquires UK-based Truckman 4×4 Accessories. |

| 2021 | Begins $30M redevelopment of Kilsyth HQ and factory. |

| 2022 | OME partners with Bilstein. |

| 2023 | Launches Earth Camper; takes 49% stake in Nacho Lights USA. |

| 2024 | Partners with 4WP and Offroad Warehouse; gains access to 70 US retail outlets. |

| 2025 | Celebrates 50 years; ASX-listed with ~$30 share price and ~$2.5B market cap. |

We recommend

-

Sponsored

SponsoredWin an ARB Earth Camper as part of ARB’s 50-year celebration

Want to win an ARB Earth Camper? It’s simple. Just join the ARB mailing list

-

Gear

GearARB releases Summit MKII bull bar for the MY24 70 Series LandCruiser

Cruise to the Summit with ARB’s latest bull bar

-

News

NewsKia Tasman gets ARB treatment in new renders

ARB previews rugged Kia Tasman in new renders, showcasing bull bar, canopy, off-road wheels and more