INFINITI to Nissan is what Lexus is to Toyota, namely an upmarket sister brand. Infiniti makes a dual-range 4x4, the QX80, which is an up-spec and restyled variant of the Y62 Patrol.

But this isn’t about the QX80, rather Infiniti’s recent announcement that it has a variable compression ratio (VCR) engine that’s been 20 years in the making and is due to appear in new Infiniti models as soon as 2018. If this all comes to fruition, it will be an amazing breakthrough.

VCR engines have been one of the holy grails of automotive design, with patents dating back to the 1920s and many working prototypes in laboratories over the years. However, there’s been nothing substantial beyond that.

Some of the finer details of Infiniti’s 2.0-litre, four-cylinder (petrol) VCR engine haven’t been made public, but the in-principle design is clear to see. As with other VCR engines, Infiniti’s VCR design adjusts the compression ratio so it can make better use of forced aspiration, in this case a turbocharger. It can even adjust itself to run more efficiently than conventional engines without any help whatsoever from the turbocharger.

Turbochargers, like superchargers, help an engine produce more power by feeding in compressed air; the theory being the more air you can pump into and through an engine, the more fuel it can burn and the more power it can produce. If you stuff too much air into an engine’s cylinder and then further compress it via the piston on its compression stroke, the air can get that hot it will ignite the fuel. This is definitely not what you want in a petrol engine.

It’s the sparkplug’s job to ignite the fuel at a precise point in time and you don’t want the air/fuel mixture to randomly self-ignite. If it does it’s called pre-ignition or detonation, and it’s potentially catastrophic for the engine. The possibility of detonation can be lessened by using a turbocharger that pumps less air into the engine, but that defeats, at least in some part, the purpose of having a turbo in the first place.

Alternately, you can reduce the amount the air is compressed once it’s in the engine by reducing the compression ratio. The trouble with this is a lower compression ratio is detrimental when the engine is working without the help of its turbo, as lower compression ratios mean reduced torque and power. Furthermore, a low compression engine running high turbo boost pressures generally equates to a non-linear power delivery as the engine goes from its ‘soft’ off-boost mode to a ‘hard’ on-boost mode – not what you want for driveability.

Now you can see where this is heading. You design an engine that can vary its compression ratio to suit what the turbo is doing or not doing. When the engine is under minimum load (the vehicle is trickling along in slow-moving traffic) and the turbo isn’t doing anything (as it relies on the engine’s exhaust pressure to generate boost) you crank up the engine’s compression ratio to compensate.

Conversely, when the engine is under high loads (out on the highway pulling up a steep hill, for example) you drop the compression ratio right down and let the turbo go to town.

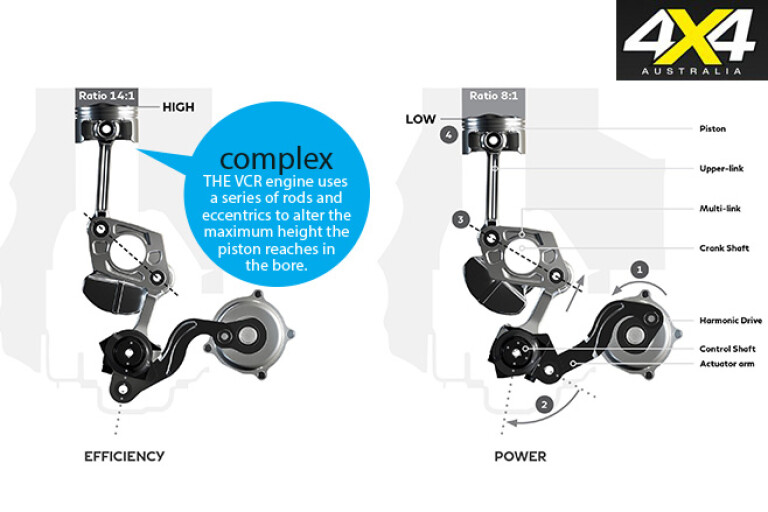

Infiniti claims that its VCR engine can vary the compression ratio seamlessly from a diesel-like high of 14:1 to a very mild 8:1. The overall control of the compression ratio, the turbo’s boost pressure, ignition timing, valve timing, etc. is done electronically and is all interlinked.

The variable intake-valve timing also means the engine can switch to an Atkinson cycle mode (see opposite), which is all part of the engine’s adaptability.

Infiniti’s VCR engine changes the compression ratio by adjusting the height the piston reaches in the cylinder, as shown in the accompanying illustration. It’s a bit unclear exactly how all this works, but the key is the so-called ‘multi-link’, which appears to adjust the crankpin offset and hence the engine’s stroke. Infiniti promises more will be revealed in the coming months.

ATKINSON CYCLE

ATKINSON CYCLE

ATKINSON cycle engines are commonplace today in petrol-electric hybrids. However, these modern Atkinson cycle engines are very different to the original Atkinson cycle engine(s) which date back to the 1880s, even if they do share a common principle.

James Atkinson came up with a number of designs, the most famous of which managed to provide intake, compression, power and exhaust strokes in one revolution of the crankshaft via a complex linkage arrangement. Conventional Otto cycle engines need two revolutions of the crankshaft to achieve the same thing.

All of Atkinson’s designs had one thing in common, namely the compression stroke was shorter than the power stroke. Modern Atkinson cycle engines achieve a similar effect by delaying the closing of the intake valves until after the start of the compression stroke. This leads to improved thermal efficiency when power production isn’t paramount.

COMMENTS