Step back in time with me to 1982. We are driving on a flat and straight country road in a 1981 4x4 Hilux single-cab farm ute. Its 2.2-litre, four-cylinder diesel claims all of 45kW – not that there’s anything particularly good or bad about that engine output. It’s just par for the day.

We’re doing 100km/h and using 10 litres of diesel every 100km we travel. Unladen, the Hilux does better than that, but today we have a decent load of hay bales on the back, so there’s more weight and, more importantly for highway driving, more aerodynamic resistance to overcome as the bales sit high and wide of the cab.

Still, 10.0L/100km is good. It means we are using just 100ml of diesel for every kilometre we travel. That would fill just over a quarter of a beer can – not much diesel at all to propel a well-laden ute a full kilometre. That’s testament to how much energy is stored in diesel fuel.

But there’s a catch. To successfully release all that energy, you need to ignite and burn the diesel in the engine’s combustion chambers and to do that you need a truckload of air. In fact, the amount of air needed to efficiently burn that small 100ml of diesel is about what would be contained within the 1.5x1.5x0.5m tub of a modern dual-cab ute; about one cubic metre, or 1000 litres worth of air.

Let’s say I put my foot down. As you’d expect, not much happens. The engine makes more noise, but the ute doesn’t accelerate with any haste. More power is needed to go significantly faster, but to get more power we need to burn more fuel. Getting the extra fuel into the engine is relatively simple, but getting the extra air into the engine to mix with that extra fuel is far more difficult, given the huge volumes of air involved.

At this point, the little four-cylinder diesel with its single overhead-cam two-valve cylinder head has pretty much reached the point where it can’t pump any more air into its cylinders, no matter how hard it tries.

What our engine needs is help, and help eventually comes in the form of a turbocharger – not for this 1981 ute, but down the track, with the further development of diesel engines.

In simple terms, the turbocharger is an additional air pump that helps the engine, because two ‘pumps’ are better than one. The extra air that the turbocharger pumps into the engine can be used to burn more fuel – which in turn releases more energy and makes more power.

The beauty of the turbocharger is that it’s relatively simple to fit to an existing engine and uses a ‘free’ energy source, as it’s driven by exhaust-gas pressure, which is energy that would otherwise be lost to the engine.

The beauty of the turbocharger is that it’s relatively simple to fit to an existing engine and uses a ‘free’ energy source, as it’s driven by exhaust-gas pressure, which is energy that would otherwise be lost to the engine.

But things haven’t stopped there with diesels. Rather than bolting a turbo on to an engine with a simple two-valve cylinder head, you can bolt one on to an engine with a free-breathing, four-valve head operated by twin overhead cams. This helps with pumping even more air into the engine and also means even bigger turbochargers can be used.

Bigger turbos can pump more air than smaller ones, but there’s still a limit to how big you can go. Bigger turbochargers need more exhaust-gas pressure to drive them and therefore take longer to respond and don’t necessarily work well all the time. Ideally you want the quick response of a small turbo combined with the pumping capacity of a big turbo.

Enter the variable-geometry or variable-vane turbo. By changing the diameter of the inlet tract to the turbo’s turbine (see ‘Turbo Basics’ sidebar), this type of turbo can improve response without sacrificing pumping capacity.

Better still is the use of two turbochargers; a smaller turbocharger, which responds quickly, even to moderate exhaust-gas pressures, and a bigger turbocharger, which can ultimately pump lots of air. That way you can optimise both response and performance.

And that’s where we are today with the most sophisticated diesel engines in modern utes, namely, the new Nissan NP300 Navara and the VW Amarok.

Like the engine of our 1981 2.2-litre Hilux, the modern utes still have small capacities – 2.0 litres in the Volkswagen and 2.3 litres in the Navara – but where the old naturally aspirated Hilux made 45kW at best, the Volkswagen peaks at 132kW and the Nissan at 140kW. That is roughly three times the amount of power. Not that you need any more power to drive that same load of hay down the road at 100km/h.

Turbo Basics

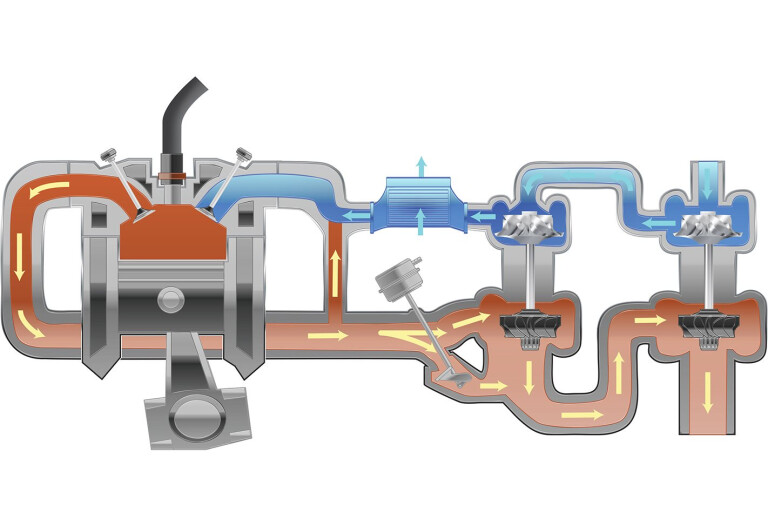

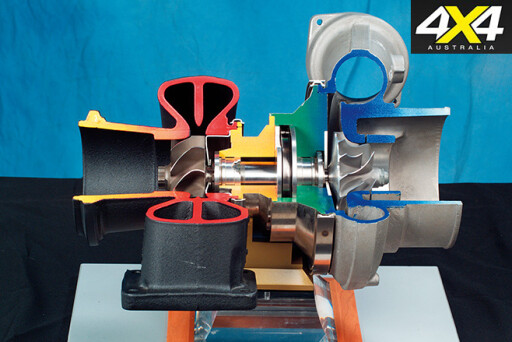

A turbocharger consists of a turbine and a compressor, housed separately but fixed to a common shaft or axle.

The way the turbocharger works is simple: exhaust-gas pressure from the engine drives the turbine, which drives the turbo’s shaft. The shaft then drives the compressor wheel, which captures air, compresses it and pumps it into the engine, which benefits enormously by being fed with compressed air, rather than air at atmospheric pressure. It allows the engine to burn more fuel and to make more power.

The turbo’s characteristics and how it ‘adds’ to the engine’s performance can be optimised by varying the overall and relative sizes of the compressor and the turbine. The total volume of air and the pressure at which that air is delivered to the engine can be varied to produce different power characteristics.

COMMENTS